Manufacturing

Overview

There is a quiet revolution taking place in manufacturing and technology in general. I am beyond saying this is good or bad, this is inevitable. Open sourced technology is where the design of a technology is made freely available. It has been going on for a long time in software, but it is now hitting manufacturing.

Here is an example of a community that is focused on sharing innovations.

3D Printing

3D printing takes digital designs and prints them in successive layers in plastic (or a variety of other feedstock). To some this may seem a geek toy, and a continuation of the madness that got us here in the first place, but it actually has far reaching implications both for economies and the environment.

Firstly we will look at what it can produce, a lot of these you might be justified in saying why the hell would I want that but the point is the diversity;

Wind turbine: http://3dprint.com/63526/3d-printed-urban-wind-turbine/

http://www.digitaltrends.com/home/useful-3d-printed-household-items/

http://www.3ders.org/3d-printer/what-can-you-make.html

http://au.askmen.com/entertainment/galleries/top-50-things-you-can-make-with-a-3d-printer-38.html

One of the most compelling reasons for continuing to read is that if you can print it, then it doesn't have to be shipped to you. Oh, and replacement parts, when older equipment fails it can become difficult to find parts.

For most of this article I am focusing on open source RepRap printers. That is self-REPlicating RAPid prototyping machines, in short, 3D printers capable of printing their own components.

http://reprap.org/wiki/Main_Page

There are many types of 3d printers available but the ones I am discussing work by a process known as Fused Deposition Modeling (FDM). Fancy name but an easy process to understand;

http://en.wikipedia.org/wiki/Fused_deposition_modeling

Now it is not essential to have your own printer, there is a company called Shapeways, Amazon too now, that will do the printing for you. You design it, they print it. But I am going to assume you want to do something as sustainable as possible.

Is it economical?

http://www.appropedia.org/Life-cycle_economic_analysis_of_distributed_manufacturing_with_open-source_3-D_printers

Is it sustainable?

If you envisage buying plastic from wholesalers then probably not. What about buying filament from your local recycling centre? Well that is better. What about recycling your own plastic waste? That is even better. Make bioplastics yourself? Hell yeah.

http://www.earthisland.org/journal/index.php/elist/eListRead/can_we_3d_print_our_way_to_sustainability/

Feedstock

The production of 1 kg of polyethylene (PET or LDPE), requires the equivalent of 2 kg of oil for energy and raw material (see here). Polyethylene PE is the most commonly used plastic for plastic bags.However, plastics are organic polymers and certain forms can be made naturally, and others can be reused. Reuse will be discussed later. Here let's talk about bioplastics, that is a form of plastic that is derived from nature.

Bioplastics themselves aren't that hard. If a kid in a kitchen could do it;

http://www.instructables.com/id/Making-BioPlastics-Environmentally-Friendly-Plast/?ALLSTEPS

Specifically the bioplastic I find most intriguing is algae based, and yes, you can do that in a kitchen as well;

http://green-plastics.net/posts/39/how-to-make-algae-bioplastic/

Finally it appears that agricultural waste can be easily converted into bioplastic;

http://www.newscientist.com/article/dn25944-an-easier-way-to-turn-plant-scraps-to-plastics.html#.VVBg1o6qpBc

Generating a feedstock locally and sustainably is very important.

"They found that making their own 3D printing feedstock used about one-tenth the energy needed to acquire commercial filament, and used less energy than recycling the plastic conventionally."

The full potential economic impact of 3D printing is discussed here;

http://3dprintingindustry.com/2014/12/06/quantitative-3dp-sustainability-study/

http://green-plastics.net/posts/39/how-to-make-algae-bioplastic/

Finally it appears that agricultural waste can be easily converted into bioplastic;

http://www.newscientist.com/article/dn25944-an-easier-way-to-turn-plant-scraps-to-plastics.html#.VVBg1o6qpBc

Generating a feedstock locally and sustainably is very important.

"They found that making their own 3D printing feedstock used about one-tenth the energy needed to acquire commercial filament, and used less energy than recycling the plastic conventionally."

The full potential economic impact of 3D printing is discussed here;

http://3dprintingindustry.com/2014/12/06/quantitative-3dp-sustainability-study/

A cleaner environment

By reusing plastic we reduce emissions. How much? On average a 1kg of plastic requires 85MJ of energy to produce. That is 0.014 Barrels of oil or nearly 2kg. To be accurate some of that energy is contained in the material itself.One way to make filament is to take waste plastic and put it through an extruder to create filament. That is, to recycle it. By recycling 1kg we reduce emissions 2kg. Now there will be energy required to perform the recycling, but I think it is safe to say it is better to recycle.

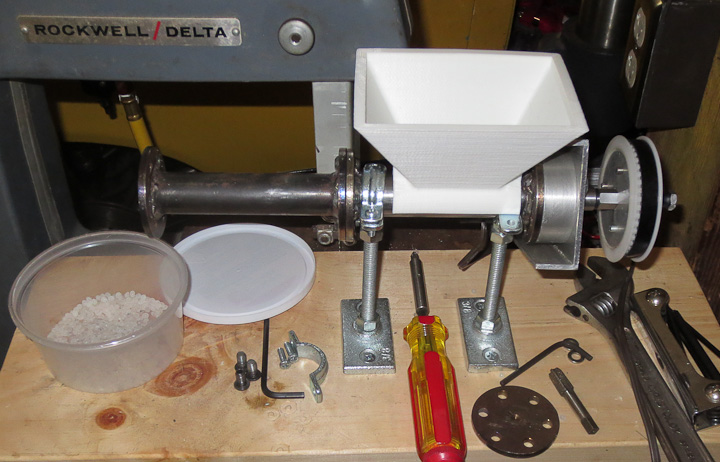

To do this at home checkout the recyclebot.

"Centralized recycling of polymers is often uneconomic and energy intensive due to transportation embodied energy. This paper provides a proof of concept for high-value recycling of waste polymers at distributed creation sites."

On a cheap industrial scale the Plastic Bank has brought out the open source extruder;

http://plasticbank.org/extruder/

http://www.appropedia.org/Plastic_Bank_Extruder_v1.0

"About 15 million waste pickers worldwide collect, sort, and process recycled materials, but more often than not, they live in extreme poverty, making up some of the most disadvantaged communities on the planet. The Ethical Filament Foundation was created to address this very problem, and create a fair trade standard and certification process for the 3D printer filament industry."

http://www.techrepublic.com/article/how-recycled-plastic-for-3d-printing-will-drive-sustainability-and-raise-the-social-conscious-of-business/

http://3dprintingindustry.com/2014/12/06/quantitative-3dp-sustainability-study/

But it goes further than that. CO2 can be converted into plastic! Before getting too carried away let's state categorically that the amounts involved in no way would impact atmospheric CO2 levels. However, something is better than nothing.

http://breakingenergy.com/2014/01/30/co2-based-plastics-and-polymers-attract-powerful-investors/

http://www.appropedia.org/3-D_printer

http://plasticbank.org/extruder/

http://www.appropedia.org/Plastic_Bank_Extruder_v1.0

"About 15 million waste pickers worldwide collect, sort, and process recycled materials, but more often than not, they live in extreme poverty, making up some of the most disadvantaged communities on the planet. The Ethical Filament Foundation was created to address this very problem, and create a fair trade standard and certification process for the 3D printer filament industry."

http://www.techrepublic.com/article/how-recycled-plastic-for-3d-printing-will-drive-sustainability-and-raise-the-social-conscious-of-business/

http://3dprintingindustry.com/2014/12/06/quantitative-3dp-sustainability-study/

But it goes further than that. CO2 can be converted into plastic! Before getting too carried away let's state categorically that the amounts involved in no way would impact atmospheric CO2 levels. However, something is better than nothing.

http://breakingenergy.com/2014/01/30/co2-based-plastics-and-polymers-attract-powerful-investors/

Food systems

Houses?

Large homes with many people in them is highly efficient (think ants or bees). Used with Hempcrete this would be awesome;Open source

The great thing about all this is that the technology is freely available.http://www.appropedia.org/3-D_printer

Software Tools

Well the first is sketchup, and its free. Sketchup is where you design what you need, but you don't have to design everything yourself. Chances are that someone may have already done it for you on thingiverse. The other tool is ReplicatorG which communicates with the printer.Here's a complete discussion on how to take a model from sketchup and print it on a RepRap printer;

http://www.instructables.com/id/Basic-workflow-for-3D-design-in-Sketchup-and-3D-pr/

Printing in metal

A lot of people automatically assume that the strength of the components is inferior, but that is not true. Graphene and nano-technologies are coming out with products lighter than steel but 200 times as strong. There is however, traditional metal printing as well.Advanced Manufacturing Services in Sydney currently offer 3D printing of metal parts.

Conclusion

This has been a brief overview, but this technology has far reaching implications.

In 1919 Holden started manufacturing car bodies in Australia. At that time there were roughly 5 million people. The business was very successful. Now the population is at 24 million and the car industry is dying due to imports. However, at the time it was established there were no prior skills here. So everything was learned.

Once the logistics chains start to become much more expensive, then community manufacturing will boom. Personally I do not believe the logistics chains will fail completely. They will just become more and more expensive to use. So manufacturing may well become localized again, which would be a huge win for the environment.

In 1919 Holden started manufacturing car bodies in Australia. At that time there were roughly 5 million people. The business was very successful. Now the population is at 24 million and the car industry is dying due to imports. However, at the time it was established there were no prior skills here. So everything was learned.

Once the logistics chains start to become much more expensive, then community manufacturing will boom. Personally I do not believe the logistics chains will fail completely. They will just become more and more expensive to use. So manufacturing may well become localized again, which would be a huge win for the environment.

Some of this technology is expensive, but I think there might be some confusion with the idea of going it alone vs community living. At the bottom end of the scale RepRap printers can be purchased for $500, at the higher end Jinan Xintian Technology Co., Ltd. in China offer a 3D metal laser printer for $10,000. This is not pie in the sky stuff, and it is readily available to a community. Prices are dropping very fast.They key here is that communities need to co-operate and share.

"The final verdict, then, is that 3D printing can be greener, if it's the right kind (FDM); but again, the biggest environmental win comes from sharing the fewest tools so each has the most utilization."

http://www.greenbiz.com/blog/2013/07/19/3d-printing-environmental-win

No comments:

Post a Comment